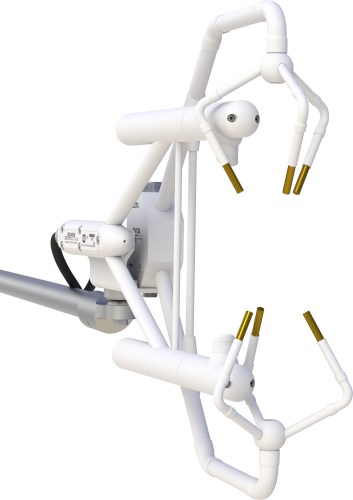

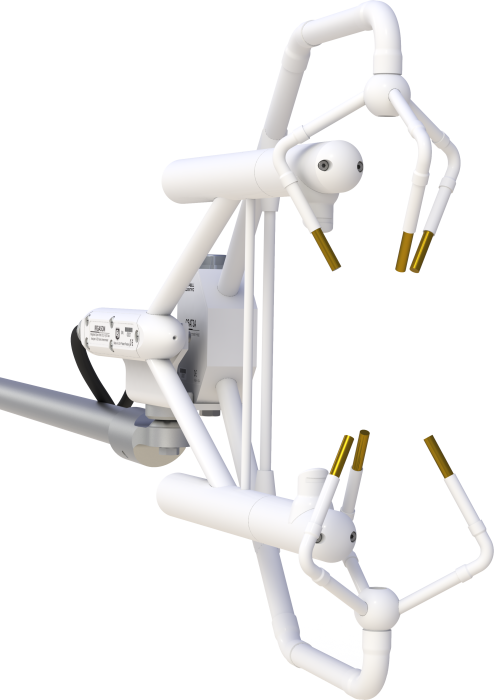

概览

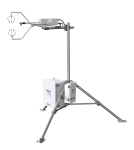

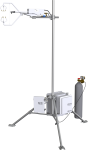

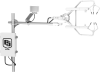

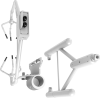

坎贝尔科学的EC150是一种开路式气体分析仪,专门设计用于涡度相关通量测量系统。作为独立工作的气体分析仪,EC150可同时测量CO2和H2O的绝对密度、空气温度和大气压力;如果带上可选的CSAT3A三维超声风速探头,EC150还可以测量三维风速和声学空气温度。

优势与特点

- New conformal coating helps protect sonic transducers in corrosive environments

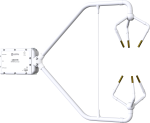

- Unique optical configuration gives a slim aerodynamic shape with minimal wind distortion

- Analyzer and sonic anemometer measurements are synchronized by a common set of electronics

- Maximum output rate of 60 Hz with 20 Hz bandwidth

- Low power consumption; suitable for solar power applications

- Low noise

- Measurements are temperature compensated without active heat control

- Angled windows to shed water and are tolerant to window contamination

- Field rugged

- Field serviceable

- Factory calibrated over wide range of CO2, H2O, pressure, and temperature in all combinations encountered in practice

- Extensive set of diagnostic parameters

- Fully compatible with Campbell Scientific dataloggers; field setup, configuration, and field zero and span can be accomplished directly from the datalogger

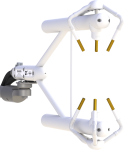

- Speed of sound determined from three acoustic paths; corrected for crosswind effects

- Innovative signal processing and transducer wicks considerably improve performance of the anemometer during precipitation events

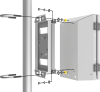

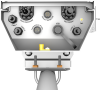

图像

技术说明

EC150输出以下变量:

- Ux (m/s)*

- Uy (m/s)*

- Uz (m/s)*

- 声温 (°C)*

- 超声诊断值*

- CO2 密度 (mg/m3)

- H2O 密度 (g/m3)

- 气体分析仪诊断值

- 环境气温 (°C)

- 大气压力 (kPa)

- CO2 信号强度

- H2O 信号强度

*前面的5个输出变量需要CSAT3A三维超声风速探头。

产品规格

| 操作温度范围 | -30° to +50°C |

| Calibrated Pressure Range | 70 to 106 kPa |

| Power | 5 W (steady state and power up) at 25⁰C |

| Measurement Rate | 60 Hz |

| Output Bandwidth | 5, 10, 12.5, or 20 Hz (user-programmable) |

| Output Options | SDM, RS-485, USB, analog (CO2 and H2O only) |

| Auxiliary Inputs | Air temperature and pressure |

| Gas Analyzer/Sonic Volume Separation | 5.0 cm (2.0 in.) |

| Warranty | 3 years or 17,500 hours of operation (whichever comes first) |

| Cable Length | 3 m (10 ft) from EC150 and CSAT3A to EC100 |

| Weight |

|

Gas Analyzer |

|

| Path Length |

15.37 cm (6.05 in.)

A temperature of 20°C and pressure of 101.325 kPa was used to convert mass density to concentration. |

Gas Analyzer - CO2 Performance |

|

| -NOTE- | A temperature of 20°C and pressure of 101.325 kPa was used to convert mass density to concentration. |

| Accuracy |

|

| Precision RMS (maximum) |

0.2 mg/m3 (0.15 µmol/mol)

Nominal conditions for precision verification test: 25°C, 86 kPa, 400 μmol/mol CO2, 12°C dewpoint, and 20 Hz bandwidth. |

| Calibrated Range | 0 to 1,000 μmol/mol (0 to 3,000 µmol/mole available upon request.) |

| Zero Drift with Temperature (maximum) | ±0.55 mg/m3/°C (±0.3 μmol/mol/°C) |

| Gain Drift with Temperature (maximum) | ±0.1% of reading/°C |

| Cross Sensitivity (maximum) | ±1.1 x 10-4 mol CO2 /mol H2O |

Gas Analyzer - H2O Performance |

|

| -NOTE- | A temperature of 20°C and pressure of 101.325 kPa was used to convert mass density to concentration. |

| Accuracy |

|

| Precision RMS (maximum) |

0.004 g/m3 mmol/mol (0.006 mmol/mol) Nominal conditions for precision verification test: 25°C, 86 kPa, 400 μmol/mol CO2, 12°C dewpoint, and 20 Hz bandwidth. |

| Calibrated Range | 0 to 72 mmol/mol (38°C dewpoint) |

| Zero Drift with Temperature (maximum) | ±0.037 g/m3/°C (±0.05 mmol/mol/°C) |

| Gain Drift with Temperature (maximum) | ±0.3% of reading/°C |

| Cross Sensitivity (maximum) | ±0.1 mol H2O/mol CO2 |

Sonic Anemometer - Accuracy |

|

| Offset Error |

|

| Gain Error |

|

| Measurement Precision RMS |

|

| Speed of Sound | Determined from 3 acoustic paths (corrected for crosswind effects) |

| Rain | Innovative ultrasonic signal processing and user-installable wicks considerably improve the performance of the anemometer under all rain events. |

Ambient Temperature |

|

| Manufacturer | BetaTherm 100K6A1IA |

| Total Accuracy | ±0.15°C (-30°C to +50°C) |

相关技术文档

说明书

技术论文

技术文档

下载

EasyFlux DL for CR6OP v.2.01 (98.2 KB) 21-07-2022

CR6 datalogger program for Campbell open-path eddy-covariance systems.

EasyFlux DL for CR6OP (CMA) v.1.01 (56.1 KB) 22-02-2022

CR6 datalogger program for Campbell open-path eddy-covariance systems.

Note: This version is customized for CMA flux format only.

ECMon v.1.6 (10.7 MB) 29-03-2016

EC100-Series Support Software.

EC100 OS v.8.02 (560 KB) 14-10-2019

EC100 Operating System.

Watch the Video Tutorial: Updating the EC100 Operating System.

Device Configuration Utility v.2.29 (54 MB) 15-11-2023

A software utility used to download operating systems and set up Campbell Scientific hardware. Also will update PakBus Graph and the Network Planner if they have been installed previously by another Campbell Scientific software package.

Supported Operating Systems:

Windows 11 or 10 (Both 32 and 64 bit)

CSAT3H Heater Controller v.14.2 (46 KB) 02-02-2021

The CSAT3H Heater Controller ships with this encrypted program. This program is for the unlikely event that the program needs to be re-installed or updated to a newer version. Please contact Campbell Scientific if you have questions about the program or would like the algorithm modified for a specific application.

CSAT3H Heater Controller v.14.2 (46 KB) 02-02-2021

The CSAT3H Heater Controller ships with this encrypted program. This program is for the unlikely event that the program needs to be re-installed or updated to a newer version. Please contact Campbell Scientific if you have questions about the program or would like the algorithm modified for a specific application.

EasyFlux DL for CR1000XOP v.2.01 (98.2 KB) 21-07-2022

CR1000X datalogger program for Campbell open-path eddy-covariance systems.

常见问题解答

EC150: 21

展开全部收起全部

-

The factory calibration accounts for CO2 and H2O signal strengths down to 0.7. Therefore, to ensure quality data, windows should be cleaned before signal strengths drop below 0.7.

-

The molecular sieve has been demonstrated here by our engineering department to be effective at removing CO2 and H2O from the air sample. The change was made for two reasons:

- It was a safer alternative than using the previous chemicals.

- Increased shipping regulations for the chemicals limited the number of suppliers.

-

The barometer and temperature sensor are needed because the IRGASON® and EC150 have been calibrated at the factory over a range of temperatures (-30° to +50°C) and barometric pressures (70 to 106 kPa).

-

The bottles of sieve for drop-in replacement contain the pellets and a membrane on top. The membrane is necessary to keep the pellets contained while allowing gas to pass over the zeolite. The bottle has the same footprint as the old magnesium perchlorate bottles. The amount in each bottle is listed on the bottle. The amount of sieve needed for each analyzer is the following:

- The EC150 needs 22 g (drop-in bottle).

- The IRGASON® needs 22 g (drop-in bottle).

- The EC155 needs 22 g (drop-in bottle).

- The AP200 needs 500 g (refill).

- The 27423 needs 1000 g (refill).

- The 31022 needs 500 g (refill).

-

The minimum height for the IRGASON® or EC150 should be approximately 2 m. Sensor placement below that height may result in a significant loss in frequency response. The maximum height depends on the available upwind fetch or footprint area. As a general guideline for unstable boundary layer conditions, the height of the sensor should be less than the distance from the sensor to the outermost edge of the footprint area divided by one hundred. For example, if there is 500 m of available upwind fetch, the IRGASON® or EC150 should not exceed a height of 5 m. Note that for neutral and stable conditions, the footprint area will grow.

-

The power requirement for the IRGASON® or EC150 with CSAT3A is 5 W at room temperature regardless of whether it is powering up or under steady-state operation. At extreme cold or hot temperatures, the power requirement reaches 6 W.

-

The molecular sieve is a non-hazardous material that can be shipped to any country.

-

The EC150 and IRGASON® gas analyzer windows are polished, slanted at an angle, and coated with a hydrophobic material to prevent water from collecting on their surfaces. Wicks may also be used on the windows to promote capillary action and move water away from the window edges. Also, heaters in the snouts may be turned on to help minimize data loss because of precipitation and condensation events.

-

Differences between the sonic calculated temperature and the air temperature measured by a more traditional sensor do not necessarily indicate a problem. Sonic anemometers, because of their high sensitivities to sonic geometry and transducer response time, do not typically measure absolute temperature as accurately as traditional temperature probes. Even very small changes in geometry can lead to errors in sonic temperature because sonic temperature is proportional to the square of any error in the distance between sonic transducers. As an example, a change of only 200 micrometers in sonic path length at room temperature yields a 1°C change in measured sonic temperature.

Even though sonic anemometers are generally not recommended for measuring absolute temperature, they excel at measuring fast temperature fluctuations, which are needed for eddy-covariance calculations (sensible heat flux). Furthermore, the error in sonic temperature in most cases can be regarded as an offset after sonic temperature has been corrected for humidity, and therefore, it will not have an effect on the covariance calculation. Nevertheless, if a user desires to calibrate the sonic temperature to account for this offset, this can be done using the temperature reading from a collocated temperature probe, such as the EC150 or IRGASON® temperature probe.

-

Yes. A fine-wire thermocouple, such as a FW05, can be used.

案例研究

Scientists and land-use managers have long recognized the importance of forest lands for their role......阅读更多