可预设程序,低功耗

概览

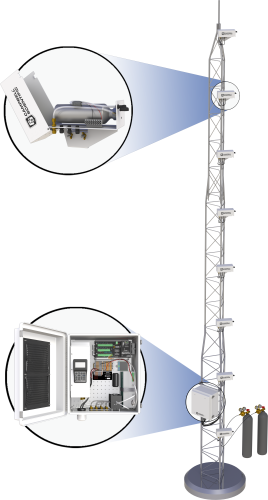

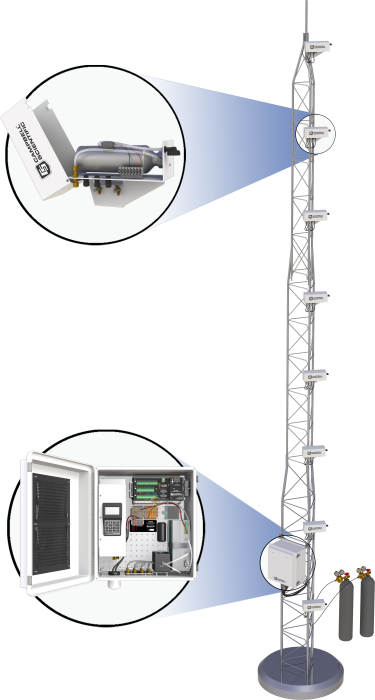

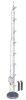

AP200是完整的集成的系统,测量CO2 和H2O 大气廓线系统。通过8个采样管测量二氧化碳(CO2)和水汽(H2O) 浓度,这些采样管通常位于塔的不同高度处,形成垂直剖面。AP200 常与涡度系统组合,测量储存项,为表面气体交换提供更完整的测量。

优势与特点

- Fully integrated system

- Requires only 13 W (average at 25°C and 12 Vdc)

- Contains a Campbell Scientific CR1000X Measurement and Control Datalogger

- Automatically performs CO2 zero and span

- Automated temperature and pressure control

- Data logger program included

图像

技术说明

测量

主要参数

- CO2在每个采样管的浓度

- H2O在每个采样管的浓度

- 系统诊断

其它参数

- 气样流速

- 样品室压力

- 样品室温度

- 其它控制变量

产品规格

System Enclosure |

|

| Operating Temperature | -30° to +45°C |

| Power Requirements |

|

| Dimensions | 52.1 x 44.5 x 29.7 cm (20.5 x 17.5 x 11.7 in.) |

| Weight |

|

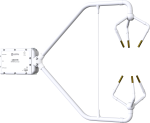

Pump Module |

|

| Pump Type | Dual-head diaphragm pump with a brushless dc motor |

| Mounting | Mounted in an insulated, temperature-controlled box inside system enclosure |

| Control | Pumping speed is automatically controlled to maintain the pump inlet pressure at the set point |

| Maximum Pumping Speed | 9.0 liters per minute (LPM) |

| Pressure Sensor Range | 15.0 to 115.0 kPa |

| Heater | 8.0 W (turns on/off at 2°C) |

| Warm-up Time | ~50 min (from -30° to +2°C) |

| Fan | 0.7 W (turns on at 50°C and off at 45°C) |

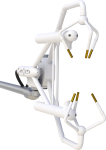

Valve Manifold |

|

| Mounting | Mounted inside system enclosure |

| Inlets | Eight air sample inlets plus one inlet for zero, one inlet for CO2 span, and one inlet for H2O span |

| Connections | 0.25-in Swagelok |

| Mass Flow Sensor | 0 to 1.0 standard liters per minute (SLPM) |

| Heater | 8.0 W (turns on/off at 5°C) |

| Warm-up Time | ~20 min (from -30° to +4°C) |

| Fan | 0.7 W (turns on at 45°C and off at 43°C) |

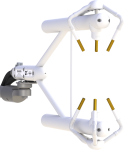

Intake Assembly |

|

| Filter | 1.0-in diameter, sintered stainless-steel disk filter, 10-micron pore size |

| Orifice Heater | 2 kohm (0.07 W at 12 Vdc) |

| Mixing Volume | 750 mL |

| Sample Connection | 0.25 in. Swagelok |

| Number of Connections for Heater Cable Entry Seals | 3 (1 in, 2 out) |

| Cable Diameter for Heater Cable Entry Seals | 2.8 to 6.6 mm (0.11 to 0.26 in.) |

| Wire Diameter for Heater Cable Screw Terminals | 26 to 12 AWG |

| Wire Stripping Length for Heater Cable Screw Terminals | 5.0 mm (0.2 in.) |

| Screw Tightening Torque for Heater Cable Screw Terminals | 0.4 N•m |

| Orifice Inside Diameter | 0.178 mm (0.007 in.) |

| Dimensions | 31 x 12.5 x 19 cm (12 x 5 x 7.5 in.) |

| Weight | 1.4 kg (3.1 lb) |

相关技术文档

下载

AP200 CR1000 Program v.2.01 (31.3 KB) 12-01-2021

AP200 CR1000(X) Program.

Compatible with the LI-850.

Note: For those with the LI-840 contact Campbell Scientific for compatible code.

Device Configuration Utility v.2.33 (49.6 MB) 07-07-2025

A software utility used to download operating systems and set up Campbell Scientific hardware. Also will update PakBus Graph and the Network Planner if they have been installed previously by another Campbell Scientific software package.

Supported Operating Systems:

Windows 11 or 10 (Both 32 and 64 bit)

常见问题解答

AP200: 42

展开全部收起全部

-

No. The AP200 requires flow from at least four intake assemblies for smooth operation of the pump.

-

The AP200 supports automatic zero/span from once per day to once each averaging period (typically 30 minutes). A zero/span once a day will mitigate zero/span drift caused by seasonal temperature changes and long-term drift in the IRGA. More frequent zero/span (hourly) will also correct for any small drift associated with 24 hour temperature swings.

-

No. The tubing can be purchased from another vendor. When making a purchase, remember that Campbell Scientific recommends Synflex 1300, ¼ in. outer diameter (OD) tubing for the AP200.

-

Adding sensors to the AP200 is not recommended.

-

The spacing depends on the canopy and atmospheric conditions. It is important to know where the concentration gradients are the steepest.

For example, in a low agricultural crop canopy, it may be appropriate to use a logarithmic distribution within and near the top of the canopy, and a linear distribution above the canopy: 0.2 m, 0.4 m, 0.8 m, 1.6 m, 3.2 m (logarithmic) and 5 m, 7 m, 9 m (linear).

-

The AP200 has two power input terminals that are individually diode protected. Connect one power system to each terminal.

-

No. The AP200 is designed to work only with an LI-840 or an LI-840A.

-

If the dewpoint generator is already stable, and a short piece of Bevaline tubing is used to connect it to the AP200, then it should only take a few minutes for the H2O reading to stabilize.

-

Campbell Scientific recommends Synflex 1300 (pn 15702, Raw Plastic Tubing .250 in. OD). This tubing has a durable polyethylene jacket and an aluminum wrap to limit diffusion through the wall. The aluminum layer also makes this tubing easier to work with, as it does not tend to spring back into a coiled shape as much as other tubing types.

-

No. Because the AP200 has only eight inlets for air samples, it can only operate with a maximum of eight intake assemblies.

案例研究

This case study discusses the integration of CPEC310 and AP200 systems to explore the theories......阅读更多