管理充电电压和电流,保护电池

概览

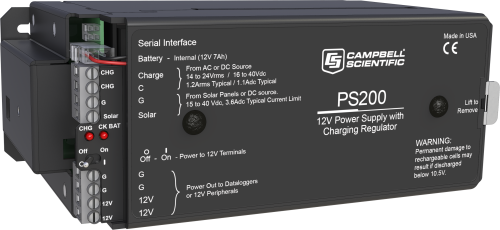

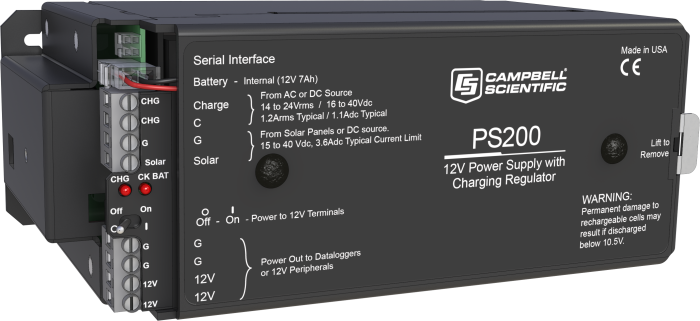

PS200 是一个12-Vdc 的电池加上一个充电保护器。保护器管理充电电流和电压,安全优化来自交流适配电源或太阳能板的充电。它还可以测量不同的输入、输出和状态参数,允许在充电和使用期间紧密地监测电池。PS200 包含一个12-Vdc 的铅酸电池,而CH200 充电控制器是与用户提供的电池搭配使用。

优势与特点

- 电池极性反接保护

- 实时测量充电输入电压、电池电压、内置温度、电池电流和负载电流

- 防止大电流和大电压损坏供电电源

- 可同时监测负载和电池电流的能力

- 允许同时连接两个充电电源(例如:太阳能板,市电充电器)

- 两级常电压充电和温度补偿功能,优化了电池充电,增加了电池的使用寿命

图像

3D/CAD 文件:

相似产品

技术说明

PS200 供电电源包含可充电的7 Ah阀控铅酸电池(VRLA),和一个充电保护器。这种基于微控制器的充电保护器,提供两路的常电压充电和温度补偿,优化电池的充电和增加电池的使用寿命。

两路输入端子可以同时连接两种充电电源。PS200还引入了最大功率点追踪算法,用于太阳能输入,最大化可用的太阳能充电。RS-232 和 SDI-12 端子允许PS200将充电参数传送给数据采集器。

PS200具有几个安全特征,用来保护充电源、电池、充电保护器和负载设备。SOLAR – G 和 CHARGE – CHARGE输入端子引入了硬件电流限制和极性反转保护。

故障防护和自恢复的热保险可以保护CHARGE – CHARGE输入免受灾难性的AC/AC 或 AC/DC 充电源故障的影响。另一个自恢复的热保险保护12 V输入端子免于输出负载故障的影响。

PS200还具有电池极性反转保护功能,以及包括ESD和电涌防护,PS200的所有输入和输出。

产品规格

| Operational Temperature | -40° to +60°C (VRLA battery manufacturers state that “heat kills batteries” and recommend operating batteries at ≤ 50°C.) |

| Dimensions | 19 x 7.6 x 10.6 cm (7.5 x 3 x 4.2 in.) |

CHARGE - CHARGE Terminals (AC or DC Source) |

|

| AC | 18 to 24 VRMS (with 1.2 ARMS maximum) |

| DC | 16 to 40 Vdc (with 1.1 Adc maximum) |

SOLAR Terminals (Solar Panel or Other DC Source) |

|

| -NOTE- | Battery voltages below 8.7 V may result in less than 3.0 A current limit because of fold-back current limit. |

| Input Voltage Range | 15 to 40 Vdc |

| Maximum Charging Current | 4.0 Adc typical (3.2 to 4.9 Adc depending upon individual charger) |

Quiescent Current |

|

| No Charge Source Present | 300 μA maximum |

| No Battery Connected | 2 mA maximum |

Battery Charging |

|

| -NOTE- | Two-step temperature-compensated constant-voltage charging for valve-regulated lead-acid batteries; cycle and float charging voltage parameters are programmable with the default values listed. |

| CYCLE Charging | Vbatt(T) = 14.70 V - (24 mV) x (T-25°C) |

| FLOAT Charging | Vbatt(T) = 13.65 V - (18 mV) x (T-25°C) |

| Accuracy | ±1% (on charging voltage over -40° to +60°C) |

Power Out (+12 Terminals) |

|

| Voltage | Unregulated 12 V from battery |

| 4 A Self-Resettable Thermal Fuse Hold Current Limit |

|

Measurements |

|

| -NOTE- | At -40° to +60°C |

| Average Battery Voltage | ±(1% of reading + 15 mV) |

| Average Battery/Load Current Regulator Input Voltage |

±(2% of reading + 2 mA) Impulse type changes in current may have an average current error of ±(10% of reading + 2 mA). |

| Solar |

±(1% of reading - 0.25 V) / -(1% of reading + 1 V) 1.0 V negative offset is worst-case due to reversal protection diode on input; typical diode drop is 0.35 V. |

| Continuous |

±(1% of reading - 0.5 V) / -(1% of reading + 2 V) 2.0 V negative offset is worst-case due to two series diodes in AC full-bridge. Typical diode drops are 0.35 each for 0.7 V total. |

| Charger Temperature | ± 2°C |

下载

PS200 Example Programs v.1.2 (36.4 KB) 02-12-2025

CR1000 programming examples for use with the PS200. The examples show how to use both SDI-12 and RS-232 advanced instruction programming techniques.

CH200 / PS200 OS v.11 (434 KB) 24-04-2020

Execution of this download installs the CH200 / PS200 Operating System on your computer.

Note: The Device Configuration Utility is used to upload the included operating system to the CH200 / PS200.

常见问题解答

PS200: 8

展开全部收起全部

-

Yes. The G and 12V terminals on the charge regulator are used to connect the black and red wires that connect with the green connector, which provides power to the data logger.

-

The PS100, PS150, and PS200 models take in AC or DC power from a wall transformer or a solar panel. The internal regulator controls the charge to the battery to make sure the battery doesn’t become overcharged (based on temperature).

If the switch is on, the voltage from the battery will flow back out from the regulated battery to the loads; however, the voltage on that battery may be 11.9 V, 13.2 V, or some other value that the battery happens to be at. It is important to understand that the voltage will not always be exactly 12.0 Vdc. Rather, the voltage will float up or down as the battery is recharged or depleted.

-

The voltage from a solar panel will fluctuate throughout the day.

If AC power is being used, the voltage is usually stable.

The voltages coming into the regulator inputs are controlled so that the battery won’t be overcharged (and thus ruined by boiling out the electrolyte). If the battery connected to the regulator is good, the highest voltage you will likely see is just above 14 Vdc in the extreme cold, but normally it should be around 13.2 Vdc.

If you have a nearly dead battery (to be checked with a voltmeter) or a battery with shorted cells, you will see a very low battery voltage. The lowest voltage you will see on the data logger data is usually about 10.0 V because the data logger will shut down near that level and then wait for the voltage to increase to an 11- or 12-volt level.

The ripple voltage is a few millivolts flowing into the battery, but the battery should filter out most of that noise, providing a pretty stable voltage.

-

Look for a stamp on top of the battery. The stamp may be in a date format of YYMMDDXX where:

- YY is the year.

- MM is the month.

- DD is the day.

- XX is the manufacturing plant.

This indicates the age of the battery.

-

Battery manufacturers recommend that their batteries be charged at least once every 3 to 6 months. If an extra wall charger is available, such as a 29796, Campbell Scientific recommends keeping it continually connected to ac power.

-

Yes. A properly designed system with a PS100 or PS200 can keep a CR1000 working continuously during a short power failure. Campbell Scientific recommends, however, conducting a load analysis to determine what duration of power outage can be endured.

-

The PS100 is a float-only charger that is limited to a 20 W solar panel and a maximum load of approximately 1 A.

The more advanced (and more expensive) PS200 is a multistage controller that can charge at higher rates and use larger solar panels (90 W) while delivering a maximum of approximately 4 A to the load, depending on the temperature. The PS200 is a smart charger that incorporates MPPT (maximum power point tracking) technology and can be interrogated by the data logger to check its state, solar panel status, load currents, battery voltage, and net battery current. In this regard, the PS200 acts as a high-tech sensor, as well as a charge regulator.

The PS100 has a temperature sensor for temperature compensation. The PS200 has a similar onboard temperature sensor, but it is more efficient and does not dissipate as much heat with a similar load. The PS200 also has a feature where an independent battery temperature measurement can be sent to the charger rather than using its onboard temperature sensor.

-

The CH200 or PS200 will pull power only from the source with the highest voltage at that moment. For example, the regulator will take the 20 W input from the 24 Vdc wall transformer rather than from the 18 V 50 W solar panel—even during the day. If the power goes out, the 50 W solar panel will charge during the day with no charging at night.

案例研究

In the mountains of Antioquia, Colombia, eight of the region’s most important dams now share......阅读更多